Continuous improvement is a systematic and ongoing process to enhance the efficiency, effectiveness, and overall performance of an organization, product, or process. Rooted in the philosophy of incremental progress, continuous improvement involves identifying and implementing small, ongoing changes to achieve greater productivity, quality, and customer satisfaction over time.

Continuous improvement is a systematic and ongoing process to enhance the efficiency, effectiveness, and overall performance of an organization, product, or process. Rooted in the philosophy of incremental progress, continuous improvement involves identifying and implementing small, ongoing changes to achieve greater productivity, quality, and customer satisfaction over time.

By fostering a culture of learning and innovation, continuous improvement empowers organizations in all industries to evolve and refine their practices, ultimately contributing to sustained growth and success in a dynamic and ever-changing environment.

The DMAIC framework is a structured methodology employed in Six Sigma and other process improvement initiatives. Designed to address and enhance existing processes systematically, DMAIC provides a roadmap for organizations to identify, analyze, and rectify issues, ultimately leading to increased efficiency, quality, and customer satisfaction.

What is DMAIC?

DMAIC is an acronym that stands for Define, Measure, Analyze, Improve, and Control. It is a systematic and data-driven methodology used in Six Sigma and other process improvement initiatives. DMAIC provides a structured framework for organizations to identify, measure, analyze, improve, and control existing processes to enhance efficiency, reduce defects, and improve quality and customer satisfaction. Each phase of the DMAIC framework represents a crucial step in the process improvement journey, ensuring a systematic and evidence-based approach to problem-solving and optimization.

DMAIC is widely used in various industries to enhance processes and drive continuous improvement. Here are a few examples of DMAIC in action:

Manufacturing:

DMAIC may be applied in a manufacturing setting to improve product quality, reduce defects, and increase production efficiency. For instance, a company might use DMAIC to identify and address issues in a production line, leading to reduced cycle times and improved overall quality.

Healthcare:

DMAIC can be employed in healthcare to optimize patient care processes and enhance operational efficiency. For example, a hospital might use DMAIC to streamline patient discharge, reduce wait times, minimize errors, and improve overall patient satisfaction.

Financial Services:

In the financial sector, DMAIC can be utilized to improve customer service, risk management, and transaction processing processes. For instance, a bank might apply DMAIC to analyze and improve the efficiency of its loan approval process, leading to faster decision-making and reduced errors.

Supply Chain Management:

DMAIC is valuable in optimizing supply chain processes. An organization might use DMAIC to analyze and improve inventory management, reduce excess stock levels, minimize stockouts, and enhance overall supply chain performance.

Information Technology:

DMAIC can be applied in IT to improve software development processes or enhance IT service delivery. For example, a software development team might use DMAIC to identify and eliminate bottlenecks in the development life cycle, resulting in faster delivery of high-quality software.

Customer Service:

Organizations providing customer service can use DMAIC to enhance their service delivery processes. A call center, for instance, might apply DMAIC to analyze and improve the handling of customer inquiries, leading to reduced wait times and increased customer satisfaction.

Implementing the DMAIC methodology can pose several challenges for organizations. Some common challenges include:

Resistance to Change:

Employees and stakeholders may resist changes to established processes. Overcoming resistance requires effective communication, training, and a commitment to illustrating the benefits of the improvements.

Data Quality Issues:

DMAIC relies heavily on accurate and reliable data for analysis. Poor data quality can lead to incorrect conclusions and hinder the identification of root causes. Organizations need to invest in data collection and validation processes, including DMAIC software.

Inadequate Training and Skills:

Teams involved in DMAIC projects must possess the necessary skills and training in statistical analysis, process mapping, and problem-solving techniques. Inadequate training can result in ineffective implementation and suboptimal outcomes.

Unclear Project Scope and Objectives:

Defining a clear project scope and objectives is crucial in the Define phase. Ambiguity in these areas can lead to misalignment between project goals and organizational priorities, causing confusion and hindering progress.

Lack of Leadership Support:

Successful DMAIC implementation requires strong leadership support. If leaders are not fully committed to the process, it may be challenging to secure the necessary resources, overcome organizational barriers, and drive a culture of continuous improvement.

Complexity of Processes:

In cases where processes are highly complex, it can be challenging to identify and understand all relevant factors influencing performance. Organizations must strike a delicate balance by simplifying complex processes for analysis without oversimplifying them.

Limited Cross-functional Collaboration:

DMAIC often involves collaboration across different departments or functions within an organization. Limited collaboration and communication between these groups can hinder the sharing of valuable insights and the success of improvement initiatives.

Failure to Sustain Improvements:

Organizations may face challenges in maintaining the gains achieved through DMAIC. Without a robust control plan and ongoing monitoring, there is a risk of regression to previous process performance levels.

Overemphasis on Tools, Underemphasis on Culture:

Focusing solely on the tools and techniques of DMAIC without addressing the cultural aspects of continuous improvement can result in a lack of sustained commitment from employees and hinder the long-term success of improvement initiatives.

Addressing these challenges requires a holistic approach, combining effective change management, leadership commitment, skill development, and a culture that values continuous improvement.

Benefits of the DMAIC framework

The DMAIC approach offers several benefits to organizations seeking to enhance processes and drive continuous improvement:

Improved efficiency and effectiveness

DMAIC aims to eliminate waste, reduce defects, and optimize processes. Organizations can achieve increased efficiency, reduced cycle times, and improved resource utilization by systematically identifying and addressing inefficiencies.

Enhanced problem-solving capabilities

DMAIC provides a systematic and structured approach to problem-solving, guiding teams through a sequence of defined steps. This structured framework helps ensure that issues are thoroughly understood and addressed methodically.

Long-term sustainability of improvements

The DMAIC methodology is designed to drive initial improvements and ensure their sustainability over time. The Control phase often involves training employees on the updated processes and any new tools or methodologies introduced during the improvement effort. Ensuring personnel have the necessary skills and knowledge to sustain the improvements is crucial for long-term success.

These benefits explain why the DMAIC process is so popular and widely used.

The Phases of DMAIC

Each of the five phases of DMAIC structures improvement work so that it can be conducted systematically and continuously.

Define

The "Define" phase of DMAIC clearly outlines the project's goals, scope, and objectives. This involves identifying the problem or opportunity for improvement, defining the project's boundaries, and establishing measurable targets. The primary focus is on understanding the customer requirements and expectations. The process owner is identified, and the improvement team is formed.

Measure

The "Measure" phase involves quantifying the current state of the process under investigation. Metrics and data are collected to assess the performance of the process and establish a baseline. This step helps identify key process characteristics and understand the extent of the issue or improvement potential.

Analyze

The collected data is analyzed in the "Analyze" phase to identify root causes of problems or inefficiencies. Various tools and techniques, such as statistical analysis, process maps, and cause-and-effect diagrams, are employed to gain insights into the factors influencing the process performance.

Improve

Potential solutions are developed during the "Improve" phase, and an implementation plan is crafted. This involves testing and validating changes to the process based on the insights gained in the previous phases. The goal is to optimize the process and address the identified issues to achieve the desired improvements.

Control

The "Control" phase focuses on sustaining the improvements achieved. Control measures are implemented to ensure that the process remains within acceptable limits. This involves developing monitoring systems, standardizing procedures, and establishing ongoing feedback mechanisms to prevent a regression to previous performance levels. Six Sigma software is often used to manage and monitor the control phase.

DMAIC vs. DMADV

DMAIC and DMADV (Define, Measure, Analyze, Design, Verify) are both methodologies with five phases used within the Six Sigma framework, but they serve different purposes and are applied at different stages of a project.

The DMAIC methodology is primarily used for improving existing processes and solving problems. It is applied when a recognized issue or inefficiency needs to be addressed. DMAIC is suitable for processes that are already in place but require optimization or correction. DMAIC emphasizes continuous improvement and is often applied iteratively to achieve ongoing enhancements.

On the other hand, DMADV is used for the development of new processes or products. It is applied when an organization aims to create something entirely new or significantly redesign existing processes. DMADV is suitable when starting from scratch or making substantial changes resulting in a new process or product. DMADV strongly emphasizes the design and development of new processes or products, ensuring they meet customer satisfaction requirements and needs from the outset.

In short, DMAIC is applied for continuous improvement projects, focusing on problem-solving and optimization of current performance, while DMADV is used for designing and developing new processes or products, emphasizing a structured approach to creating something entirely new or significantly redesigned. The choice between DMAIC and DMADV depends on the nature of the Six Sigma project and whether the goal is to improve an existing process or create something entirely new.

Conclusion: The Power of DMAIC for Business Optimization

The DMAIC methodology is a robust and versatile framework for organizations committed to achieving operational excellence and continuous improvement. Through its systematic approach, DMAIC provides a structured pathway for identifying, analyzing, and addressing process challenges, ultimately driving positive change and enhancing overall efficiency. The methodology's emphasis on data-driven decision-making, cross-functional collaboration, and a commitment to sustained improvement fosters a culture of excellence within organizations. DMAIC delivers immediate results as it becomes deeply embedded in an organization's DNA. It establishes a foundation for ongoing success, ensuring that processes evolve harmoniously with changing demands and that pursuing excellence remains a perpetual journey. By adhering to the principles of DMAIC, organizations can not only solve current problems but also proactively shape their future, ensuring a competitive edge in an ever-evolving landscape of challenges and opportunities.

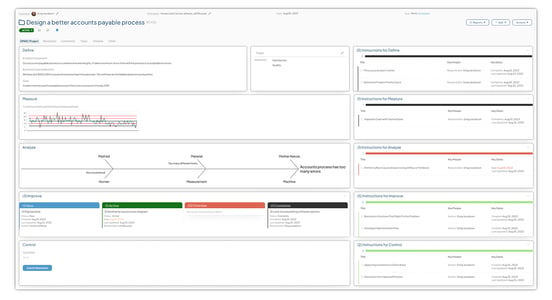

How KaiNexus Can Help

The KaiNexus platform for continuous improvement in pursuit of operation excellence helps support each phase of the DMAIC approach.

Project Management:

KaiNexus can help in the Define phase by providing a centralized platform to structure improvement projects. It allows users to articulate project goals, scope, and objectives clearly and ensures that everyone involved understands the improvement initiative.

Data Collection and Analysis:

In the Measure and Analyze phases, KaiNexus facilitates data collection and analysis. Users can input relevant metrics and data into the system, and the platform may offer tools for statistical analysis. This supports evidence-based decision-making during the DMAIC process.

Collaboration and Communication:

Effective communication and collaboration are critical in all phases of DMAIC. KaiNexus is a collaboration hub, allowing teams to discuss ideas, share insights, and work together to analyze problems and propose solutions.

Workflow Management:

For the Improve phase, KaiNexus helps manage the workflow of improvement initiatives. It includes features for task assignment, progress tracking, and milestone management, ensuring that the implementation of improvements stays on track.

Documenting Changes:

KaiNexus enables users to document changes made during the Improve phase. This documentation is crucial for understanding what changes were implemented, why they were made, and their impact on the process.

Monitoring and Control:

In the Control phase, KaiNexus helps establish control measures and monitor ongoing performance. It includes features for setting up alerts, tracking key performance indicators (KPIs), and ensuring that the improvements are sustained over time.

Reporting and Analysis:

KaiNexus offers reporting and analytics features that provide insights into the success of improvement projects. This supports the iterative nature of DMAIC, allowing organizations to learn from their experiences and refine their processes continuously.

Feedback Mechanism:

Continuous improvement involves learning from both successes and failures. KaiNexus provides a platform for capturing user feedback, enabling organizations to gather insights that contribute to refining and optimizing DMAIC processes.

Contact one of our improvement experts today for more information on how KaiNexus might support your DMAIC efforts.

Add a Comment