How to Tackle 8 Manufacturing Sales Challenges

Brooks Group

AUGUST 6, 2024

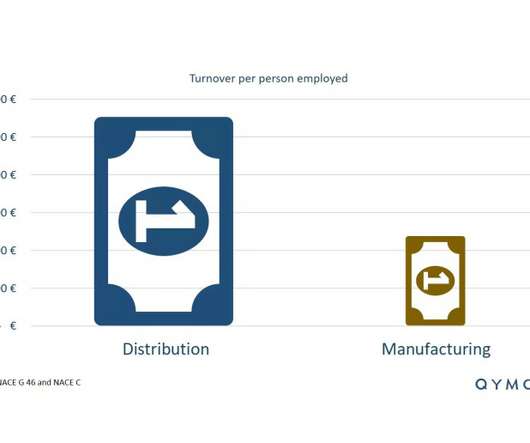

The manufacturing industry is vast, encompassing a wide variety of products and services tailored to specific industries and customer needs. Although supply chains have rightsized since the pandemic, many manufacturers are dealing with increased customer choice, greater competition, and compressed margins. Challenge 2. Challenge 3.

Let's personalize your content